Have you ever wondered about the difference between pasteurization and cooking sous vide? Both methods involve heat, but they serve different purposes. While pasteurization is primarily used to kill harmful bacteria in food through high temperatures, cooking sous vide focuses on precise temperature control to achieve perfectly cooked and tender results. In this article, we will explore the distinctions between these two techniques and uncover how they can enhance your culinary experience. So, let’s dive in and uncover the fascinating world of pasteurization and cooking sous vide!

Definitions

Pasteurization

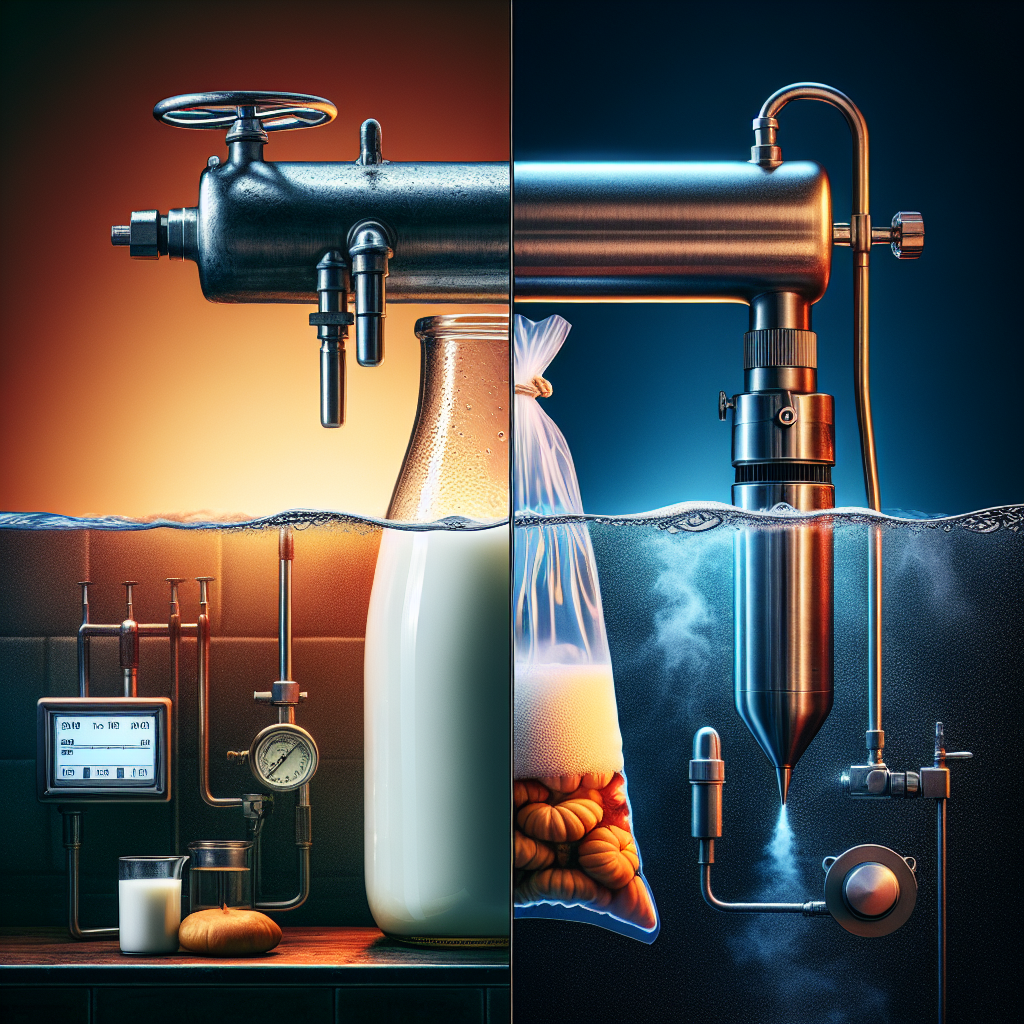

Pasteurization refers to a heat treatment process used to kill or inactivate harmful microorganisms in food products. This technique was developed by Louis Pasteur in the 19th century and is commonly used in the dairy industry to ensure the safety and extend the shelf life of products such as milk, cheese, and yogurt. During pasteurization, the food is heated to a specific temperature for a set period, effectively reducing the number of bacteria, viruses, molds, and parasites present.

Cooking Sous Vide

Sous vide, which means “under vacuum” in French, is a cooking technique that involves vacuum-sealing food in a plastic bag and cooking it at a precise temperature in a water bath. This method was initially developed for professional kitchens but has gained popularity among home cooks as well. Unlike traditional cooking methods that rely on direct heat, sous vide allows for precise temperature control, resulting in evenly cooked food with enhanced flavors and textures.

Process

Pasteurization Process

The process of pasteurization typically involves three main components: heating, holding, and cooling. The food product is heated to a specific temperature, which varies depending on the type of food and the desired result. This temperature is maintained for a specified time period, known as the holding time, which ensures the destruction of harmful microorganisms. Finally, the product is rapidly cooled to prevent any potential recontamination. Pasteurization can be achieved through various methods, including flash pasteurization, high-temperature short-time pasteurization, and ultra-pasteurization.

Sous Vide Cooking Process

Sous vide cooking involves a few simple steps. First, the desired food is placed into a vacuum-sealed bag, along with any desired herbs, spices, or marinades. The bag is then sealed to create a vacuum environment. Next, the bagged food is submerged in a precisely controlled water bath, often with the help of a sous vide immersion circulator or a specialized water oven. The cooking temperature and time are programmed and maintained throughout the process, resulting in precise and consistent cooking. Once done, the food can be finished off with a quick sear or other methods to enhance the appearance and texture.

Temperature Control

Pasteurization

Temperature control is a crucial aspect of the pasteurization process. Different types of microorganisms are more or less heat-resistant, making it necessary to use specific temperatures and time combinations to achieve the desired result. For example, milk is typically pasteurized at around 72°C (161°F) for 15 seconds, whereas fruit juices may require a higher temperature of 85°C (185°F) for about one minute. This careful temperature control ensures the elimination of harmful pathogens while preserving the taste and nutritional value of the food.

Sous Vide Cooking

One of the key advantages of sous vide cooking is the precise temperature control it offers. With this technique, the food is cooked at a specific temperature, often lower than traditional methods, for an extended period. The typical range for sous vide cooking is between 50°C (122°F) and 85°C (185°F), depending on the type of food and desired level of doneness. By cooking at precise temperatures, it is possible to achieve consistent results, ensuring that the food is cooked evenly from edge to center while retaining its moisture and tenderness.

Benefits

Pasteurization

Pasteurization offers several benefits in terms of food safety and preservation. By eliminating or reducing the number of harmful microorganisms, it significantly reduces the risk of foodborne illnesses. This is particularly crucial for vulnerable populations, such as young children, pregnant women, and the elderly. Additionally, pasteurization increases the shelf life of many food products, allowing for safer storage and distribution.

Cooking Sous Vide

Cooking sous vide provides a range of benefits in terms of flavor, texture, and convenience. The precise temperature control in sous vide cooking helps to retain the natural flavors of the food while enhancing them through the infusion of herbs, spices, and marinades. The extended cooking times at low temperatures also tenderize tougher cuts of meat, resulting in juicy and succulent dishes. Furthermore, sous vide cooking allows for easy meal preparation and batch cooking, as the food can be cooked in advance and stored, requiring only a final finishing step before serving.

Time Requirements

Pasteurization

The time required for pasteurization depends on several factors, including the type of food, the desired level of microbial reduction, and the method chosen. Shorter holding times, usually in the range of seconds to minutes, are commonly used to achieve the desired reduction while minimizing any negative impact on the quality of the food. However, for some specific applications, such as ultra-pasteurization of liquid products, longer holding times may be necessary.

Cooking Sous Vide

Sous vide cooking often involves longer cooking times compared to traditional methods. This is because the food is cooked at relatively low temperatures, often below the boiling point, to achieve the desired level of doneness. The cooking time can range from 30 minutes to several hours, depending on the thickness and type of food being cooked. However, the extended cooking times are usually hands-off, allowing for easy multitasking and ensuring consistent results without the risk of overcooking.

Equipment

Pasteurization

The equipment used for pasteurization varies depending on the scale of production and the desired method. Common equipment includes heat exchangers, pasteurizers, holding tanks, and cooling systems. These are often found in industrial settings, such as dairy processing plants. However, for home pasteurization of small batches, a stovetop pasteurizer or a water bath setup can be utilized.

Cooking Sous Vide

Sous vide cooking requires specific equipment to achieve precise temperature control. A sous vide immersion circulator is a popular choice for home cooks, as it can be attached to a pot or container filled with water. Alternatively, specialized water ovens designed for sous vide cooking offer a self-contained solution. Vacuum sealers or sealable bags are also necessary to package the food for cooking. While this equipment may require an initial investment, it provides consistent results and opens up a world of culinary possibilities.

Safety Considerations

Pasteurization

Pasteurization is a reliable method for ensuring the safety of food products. By reducing or eliminating harmful microorganisms, it greatly reduces the risk of foodborne illnesses. However, it is crucial to follow proper pasteurization protocols and guidelines to ensure the effectiveness of the process. This includes using equipment with accurate temperature control, monitoring holding times, and avoiding cross-contamination during cooling or post-pasteurization handling.

Cooking Sous Vide

When cooking sous vide, it is important to take certain safety considerations into account to prevent the growth of pathogens. While cooking at lower temperatures, there is a risk of bacteria surviving and multiplying if the food is not cooked for a sufficient amount of time. To mitigate this, it is recommended to follow reliable sous vide recipes and guidelines, ensuring that the food reaches the proper internal temperature for the required time to kill any potential pathogens. Additionally, proper hygiene and safe handling of sous vide equipment and vacuum-sealed food are essential to prevent cross-contamination.

Food Preservation

Pasteurization

One of the main benefits of pasteurization is its ability to extend the shelf life of food products. By eliminating or reducing the number of microorganisms, pasteurized products can be stored for longer periods without significant degradation in quality or safety. This is particularly advantageous for perishable foods such as milk, fruit juices, and sauces, as it allows for wider distribution, reducing waste and ensuring product availability.

Cooking Sous Vide

While sous vide cooking is primarily focused on achieving precise and delicious results, it can also contribute to food preservation. By cooking food at lower temperatures and vacu-sealing it before cooking, the growth of spoilage bacteria is minimized. This can extend the shelf life of cooked food, allowing for easier meal planning and reducing food waste. However, it is important to note that the preservation effect of sous vide cooking is not as potent as pasteurization, as it primarily targets spoilage bacteria rather than harmful pathogens.

Texture and Flavor

Pasteurization

The primary aim of pasteurization is to ensure food safety and preservation rather than altering the texture and flavor significantly. While pasteurization can cause slight changes in texture, such as the denaturation of proteins in milk, these effects are minimal and often not noticeable to the average consumer. However, pasteurization does remove certain microorganisms and enzymes that can affect the flavor of the product, resulting in a more stable and consistent taste.

Cooking Sous Vide

Sous vide cooking has gained popularity for its ability to enhance texture and flavor. By cooking food at precise temperatures for longer periods, tough cuts of meat can be rendered tender and juicy. The controlled temperature also minimizes moisture loss, resulting in a moist and succulent texture. Furthermore, the prolonged cooking time allows flavors to develop and infuse evenly throughout the food, resulting in a more intense and nuanced taste experience. Overall, sous vide cooking provides a level of texture and flavor control that is not easily achieved with traditional cooking methods.

Applications

Pasteurization

Pasteurization finds its applications in various food industries, including dairy, juice, brewing, and sauce production. In the dairy industry, pasteurized milk, cheese, and yogurt are staples of everyday life. Pasteurization also plays a critical role in the production of fruit juices, ensuring their safety and extending their shelf life. Additionally, pasteurization is utilized in the beer and wine industry to stabilize the products and prevent unwanted fermentation.

Cooking Sous Vide

The applications of sous vide cooking are vast and diverse, ranging from professional kitchens to home cooking enthusiasts. In professional kitchens, sous vide is widely used for preparing meat, fish, and vegetables with precise results. When it comes to home cooking, sous vide opens up a world of possibilities, allowing for foolproof cooking of steaks, chicken breasts, eggs, and even delicate desserts. Furthermore, sous vide can be used for large-scale meal preparation, catering, and entertaining, as it provides consistent results and frees up valuable oven or stovetop space.

In conclusion, while pasteurization and cooking sous vide may both involve heat treatments, they serve different purposes and offer distinct benefits. Pasteurization is primarily focused on food safety and preservation, ensuring the elimination or reduction of harmful microorganisms while extending shelf life. On the other hand, sous vide cooking aims to achieve precise and flavorful results, with tender and evenly cooked food. Both techniques have their applications in various food industries and can be enjoyed by home cooks looking to elevate their culinary skills. So, whether you’re looking to ensure food safety or create restaurant-quality meals at home, pasteurization and cooking sous vide have got you covered.